blown film machine pdf

The total area is 32000 square meters the modern standard workshop covers 20000 square meters. However a review of the process of blown film extrusion is worthwhile.

All Windsor Machines Limited Catalogs And Technical Brochures

Dalian Jianda Plastics Machinery CoLtd founded in 2000is specialized in RD and production of single double three and five layers of plastic film blowing machine.

. Blown film extrusion is the most important process for the production of plastic films ranging in thickness from 05 mm to as thin as 5. The Superex havø strong adaptability to resins. And some of the most effective modifications cost little more than a.

Film blowing machine is with cylinder and screw rods are made of quality alloy steel that have been nitrized and processed in a precision wayHence it is sound in hardness durable in corrosion resistance. We are producing blown film lines since 1967 and have consistently set new standards such as the development of the internal bubble cooling system and the oscillating haul-off. SmartFlex Blown Film lines 1 3 and 5 layers characterized by a competitive investment level maximized flexibility for different applications recipes power consumption reduction functional and compact layout featuring frames modularity TechnoFlex Blown Film lines for the production.

51 Introduction to Blown Film Extrusion. Production of Films Containers and Membranes. Blown Film Basics The goal of this brochure is to describe specific defects that can appear in tubular blown film and to suggest probable causes and solutions.

ABA - HDPE and LDPE. Satisfying needg o better film and higher Output. Given therefore a single screw machine is being described that has a screw of diameter 60 mm and a length of 24 screw diameters that is a LD ratio of 241.

T-shirt bags garbage bags flat bag and others. Blown Film Troubleshooting Guide Bubble Instability Chatter Die Lines Poor Heat Seal Melt Fracture Gauge V ariation cont Gels Causess Possible Solutions Dirty Air Ring Cont Check the seal between the air ring and die Check hoses for kinks or bends restricting air flow Surging of the extruder Check drive speed of the extruder. Techno FLEX Blown Film lines for the production of multi-layer film 3.

Bandera Blown Film extrusion range includes. Classicx Multi-layer 3-5 Non Barrier Blown Film Machine Introduction For Jinming Classicx models the currently-available non-barrier blown film machines are applicable to both 3-layer and 5-layer films whose width can vary from 1200mm to 3000mm. Yet avenues of improvement are open for even the most over-extended entrepreneur.

100 600mm Die gap. We have 160 employees and 70 of them are senior technicians. The polymer is melted in an extruder and the hot melt is pumped through a die to form.

15 Film Blowing Machine produce Polyethylene filmPolypropylene filmBiodegradable Plastic Filmdecomposed filmPLA filmPVA filmPBAT filmsuit to produce different bagsuich as plastic bag or biodegradable bagPLA bagPVA bagwe can produce different design film blowing machine according to different coutries customers. Elements of blown film Film thicness. This shows the arrangement of the different parts of the machine.

40 mm to 80 mm diameter Die opening. 600 4000mm Die diameter. 350 mm max LF-400 and 550 mm max LF-600 Die orifice.

Application of intelligent control technology to improve the production management. Machine Construction A cut-away drawing of a simple single screw machine is shown in Figure 1. Good melt quality means that no flow lines are created that may result in a visible or structural defect in the film.

SmartFlex Blown Film lines 1 3 and 5 layers characterized by a competitive investment level maximized flexibility for different applicationsrecipes power consumption reduction functional and compact layout featuring frames modularity. μm according to Butler 1. 08 28 mm Bubble diameter BUR blow up ratio.

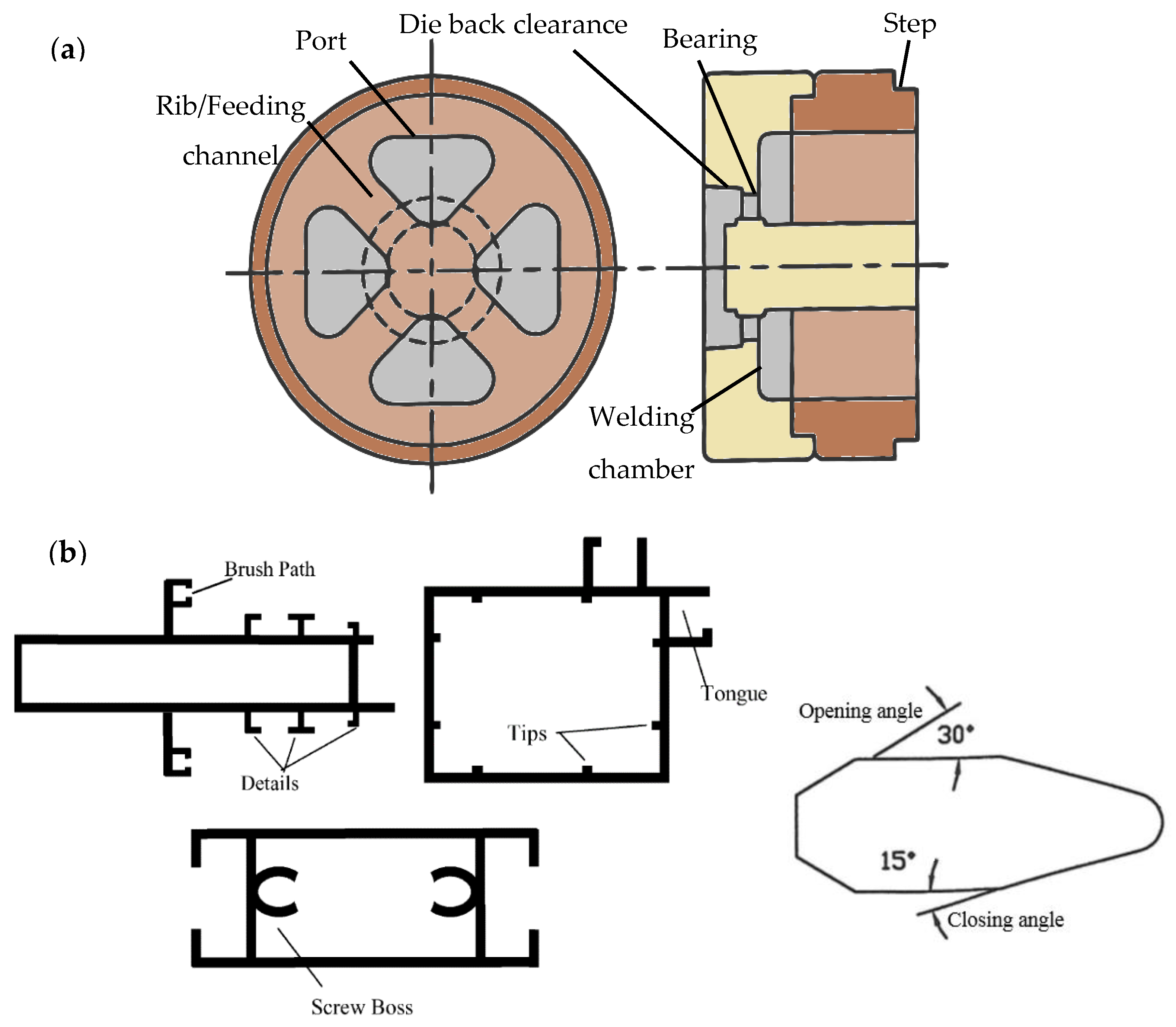

A a three layer die and B a five layer die 5. Blown film extrusion is one of the most commonly used thin gauge fabrication processes for manufacturing plastic films in the world. The specially-designed screw is of sound quality in.

An operator can become so familiar with a given film line that problems are solved intuitively but training new. 5 layers Non Barrier Blown Film Machine Product Application Introduction non barrier film launched hy high intelligent with great production performance. These Blown Film Machines and Plants are used for the manufacturing of different purposes such as bag making plastic greenhouse covering and shrink wrapping.

PDF On Dec 19 2012 John Vlachopoulos and others published Blown Film Dies Find read and cite all the research you need on ResearchGate. 37 is a schematic of a three layer blown film die 5 and Fig. 2 45 DDR draw down ratio gap widththickness x BuR MD machine direction TD transverse direction LD ratio of screw.

38 shows a photograph of a nine layer blown film production machine 6. The purpose of the blown film die is to receive polymer melt from the extruder and deliver it to the die exit as a thin annular tubular film. 08 mm std other sizes available Nip rolls top of tower can be water cooled option Similar basic features to the LF-400 LE-25 blown film line Motorized tower height adjustment is standard.

We are the manufacturer and supplier of High Density Polyethylene Blown Film Machine and Low Density Polyethylene Blown Film Machine and Plant for Biodegradable Bags for different film widths. Bandera Blown Film extrusion range includes. Drawings of multilayer blown film dies.

Blown film processors many of them small enterprises with a single plant or a single costly line may have limited resources in both capital and manpower to devote to optimizing their productivity. 300 unit per Year. Our blown film portfolio offers the right machine for your individual production needs.

4555mm or 55mm65mm screw. 6 250 microns Layflat width. Multilayer Blown Film Machine.

The machines are superior in productivity automation and film uniformity contraL Morecwer. Film width 300 1500mm. The blown film extrusion process can produce magnificent arrays of products however.

WH blown film lines are designed especially for the flexible packaging industry. The delivery of high melt quality is a performance goal not only of screw but also of any well-designed extrusion die. Working of Blown Film Extrusion Machine Units Components Purpose Pallet feeding unit Material conditioner.

Case Study Vacuum Calibration Sleeve

Jwell Machinery China Plastic Extrusion Manufacturer Supplier Company Factory

All Windsor Machines Limited Catalogs And Technical Brochures

All Windsor Machines Limited Catalogs And Technical Brochures

Metals Free Full Text Die Defects And Die Corrections In Metal Extrusion Html

Coperion And Bruckner Maschinenbau Coperion

Pdf Machine Drawing Jafer Adem Academia Edu

Shubham Extrusion An Advanced Blown Film Technology

All Windsor Machines Limited Catalogs And Technical Brochures

All Windsor Machines Limited Catalogs And Technical Brochures

Sheet Extrusion Machinery Davis Standard

Coextrusion An Overview Sciencedirect Topics

Shubham Extrusion An Advanced Blown Film Technology

New Strategies To Fabricate Starch Chitosan Based Composites By Extrusion Sciencedirect

Suzhou Tongda Machinery Blow Molding Machine Manufacturer